Excavator Hydraulic Pressure Gauge Test Kit, 9000PSI 25/40/60Mpa Test Coupling Hose Diagnostic Tool with 1 year warranty

220.61 199.71 $

ControllerThe function of the time switch machine and the water supply with time interval and partial pressure are optional functions. The controller does not have this function by default. It needs special instructions when ordering.

The controller can control one or more pumps in different working modes: one with a prepared work mode, a pump and a power pump working mode, boiler or heat exchanger unit replenishment design work mode, switch type control mode, single pump frequency mode, two pump soft start cycle control three pump soft start mode, control mode, four pump soft start control mode, a variable frequency pump station with two working mode, a variable frequency pump station with three working mode, two sets of power frequency and with a preparation of fire control work mode, a variable frequency power pump plus four Taiwan working mode.

A,System overview

SL3000Series microcomputer variable frequency water supply/The water supply controller is a computer controller designed for water supply of variable frequency constant pressure water supply system and boiler and heat exchange system. It can be used in conjunction with various brands of frequency converters. The utility model has the functions of high pressure control precision, stable pressure, second fire pressure (dynamic pressure)setting, system excess pressure water discharge automatic control, setting parameter, password locking, etc..

Two,Main performance indexes

1.Programmable settings for various pumps,You can pump up to five pumps at most1frequency conversion+4Power frequency);

2.Parameter adjustment and setting, with password lock and protection function;

ThreeThe artificial intelligent fuzzy control algorithm is adopted, which has less set parameters, high control precision, double watchdog circuit, digital filter and many anti-interference measures to prevent the software from running;

4.It can connect with passive remote pressure gauge, active voltage and current type pressure transmitter;

Five0~10VOutput control frequency voltageDC 0-10V,Can also be set asDC 0-5V;

6.With zero and full compensation function of pressure sensor;

SevenWith a regular automatic pump and pump back function, the pump can not be set to quit the cycle;

8.With second pressure (fire pressure)setting and control function;

NineWith automatic detection and protection of water shortage and external input shutdown protection function;

10.When the system is supplied with water, it has the function of setting up and controlling the overflow automatically;

ElevenWith water supply, auxiliary small pump control function, can set the small pump frequency conversion or power frequency mode;

12.It has the function of timing automatic switch and shutdown control;

ThirteenWith small flow pump sleep control function;

14.With hand operated function, can manually adjust the output voltage to control the frequency converter;

15.Can replace the electric contact pressure gauge for upper and lower pressure control;

SixteenIt has the function of water supply control with time-sharing pressure, and has six time control at most;

SeventeenWith upper limit protection pressure control function, super pressure automatic stop pump;

Three,Installation dimensions and wiring instructions

1.Controller outline size: 160mm*80mm*90mm

2.Control panel panel opening dimension * 151mm * 75mm, panel mounting.

ThreeUsing the environment as:A site where water, steam, corrosion, flammable, dust, and metal particles are not found;

4.Use ambient temperature: -20C ~50C

5.relative humidity: <95%;

6.Rated working voltage: AC220V.10%;

SevenRated power consumption of controller: <=AC 5W;

8.Controller terminal output capacity:3A/ AC220V

NinePanel and terminal description:

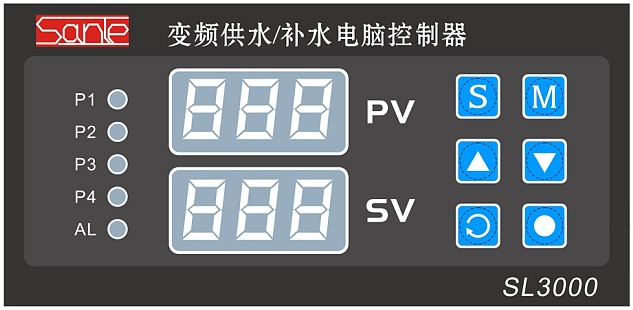

SL3000Fig. 1 Schematic diagram of type controller panel

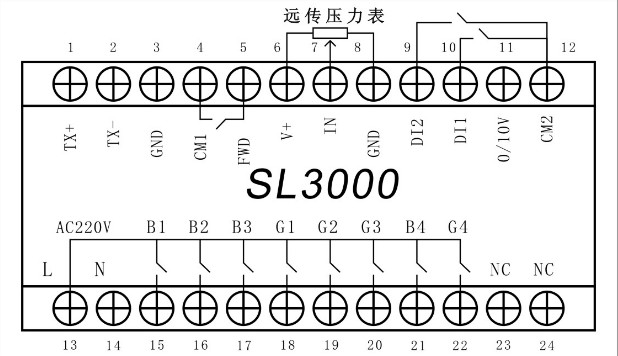

SL3000Terminal diagram of type controller

Description of connection terminals for type SL3000 controller:

1.TX+(RS485communication interface+) 2.TX - (RS485communication interface-)

3.GND (Signal ground)4.(CM1Forward runningsignal)

5.FWD (Forward running signal)6-- V+(Remote pressure gauge top+5V)

7.IN(Pressure signal input0-5V)Eight.GND(Pressure signal input ground)

9------DI2(Lack of water orStop signal input)10------(DI1Second pressure signal input)

11-----0~10V-- (DC 0-10Voutput)12------(CM2Signal common end2)

13-----(LAC 220VFire)14------(NAC 220VZero line)

15-----B1 (1#Variable frequency operation contact)16------(B22#Variable frequency operation contact)

17-----B3 (3#Variable frequency operation contact)18-----G1 (1#Power frequency running contact)

19-----G2 (2#Power frequency running contact) 20-----G3 (3#Power frequency running contact,Relief valve contact)

21-----B4 (4)#Variable frequency operation contact) 22-----G4(4#Power frequency running contact)

23-----NC() 24-----NC()

4.1:

PVSV."S""""""M"" "" """

4.2

P1P2P3P4

4.3

"S"5"S""M"" """"""S"P00=18""""P01""""P02

4.4

”S”"S"

P00----P00=18P00<>18

P01----P03<>5P01,P01""""P03=5

P02----DI1CM22P02""""P02DI1CM2P01

P03----P03many

P03=1,2B1B2P12=1B1B2P13G3P20=0

P03=3B1G1B150HzP05G1G1B1

P03=4B1G3>=(P01(P02)+P20)G3<=P01(P02)G3P20=0

P03=5,G11#G22#G3SVP21P01P21<=P012G1P05P21,G2>=P21G1G1P21,G2>=(P21+P20)G3<=P21G 3P20=0

P03=6,B1B2G1G2B1,1#1#50HzP05B1G11#3B22#2#0HzP06G11#2#>=P01+P20G3P20=0

P03=7,B1B2B3G1G2G3B1,1#1#50HzP05B1G11#3B22#2#50HzP05B2G22#3B33#

P03=8,For a frequency conversion pump, two power frequency pump mode of operation. In this work mode, the system definition B1 is frequency conversion work pump, G1 and G2 are two power frequency work pumps. When the working frequency of B1 reached 50Hz, delay P05 seconds, if the measured pressure is still less than the setting value, then connected to G1 directly start the 1# frequency pump put into operation, when the operating frequency is up to 50Hz B1 again after P05 seconds delay time, if the measured pressure is still less than the setting value, then on the G2 start 2# pumps in operation, the system depends on the working frequency of B1 pump to stabilize the pressure regulation. If the system appears overpressure, then turn off the 1# power frequency pump, then turn off the 2# power frequency pump.

P03=9,For a frequency conversion pump, three power frequency pump mode of operation. In this work mode, the system definition B1 is frequency conversion work pump, G1, G2 and G3 are three power frequency work pumps. When the working frequency of B1 reached 50Hz, delay P05 seconds, if the measured pressure is still less than the setting value, then connected to G1 directly start the 1# frequency pump put into operation, when the operating frequency is up to 50Hz B1 again after P05 seconds delay time, if the measured pressure is still less than the setting value, then on the G2 start 2# pumps in operation, if the full load operation of three pumps, delay P05 seconds, measuring the pressure still did not reach the setting value, then connected to G3, start the 3# frequency pump put into operation. If the system appears overpressure, then turn off the 1# power frequency pump, then turn off the 2# power frequency pump, and finally turn off the 3# power frequency pump.

P03=10,For two power frequency pumps, one with a fire fighting mode. In this work mode, G1 and G2 are defined as two power frequency pumps, G1 is the main pump, and G2 is the standby pump. The G3 is defined as the control terminal of the relief solenoid valve, and the B3 is defined as the alarm output terminal. Under normal working condition, the DI1 terminal has no signal input, and the PV window shows the P02 fire pressure value. The system uses P01 as low voltage, P02 as high pressure, and G1 as main pump to control the system pressure. If the pressure is measured<=P01,G1>=P02, G1 disconnect, stop the main pump. If the measuring pressure is >P02, the G3 is connected to relieve pressure. If the measuring pressure is <=P02, the discharge pressure stops. When the DI1 and CM2 terminal closed more than 2 seconds, that is, when the fire signal input, then start the G1 fire power frequency pump immediately, excessive pressure is not discharged, B3 alarm terminal is connected, the DI1 signal is removed, the pump is not stopped. In this condition, if the pressure <=P01 is measured after P05 seconds, the main pump failure or the start failure is considered, and the G2 terminal is connected at the same time, and the standby pump is started to work. In this condition, the DI2 terminal has a stop signal and the input is invalid. Only when the controller power is stopped can the status be lifted.

P03=11,For a tow five mode: a variable frequency pump, four power frequency pump mode of operation. In this work mode, the system definition B1 is frequency conversion work pump, G1, G2, G3 and G4 are four power frequency work pumps. When the working frequency of B1 reached 50Hz, delay P05 seconds, if the measured pressure is still less than the setting value, then connected to G1 directly start the 1# frequency pump put into operation, when the working frequency of B1 to 50Hz again after the delay of P05 seconds, if the pressure is still not up to the set value is on the G2 start 2# pumps in operation, and so on. If the 5 pumps put into operation, the system appears excessive pressure, then turn off the 1# power frequency pump, then turn off the 2# power frequency pump, and turn off the 4# power frequency pump in turn.

P03=12,For 1# pump and 3# pump two pump cycle soft start mode, refer to P03=6.

P03=13,For 2# pump and 3# pump two pump cycle soft start mode, refer to P03=6.

P03=14,For the 3# pump single pump frequency conversion mode, in this mode, three pumps can be switched in time and turn.

P03=15,Cycle start mode for 4 pumps. Refer to P03=7 for action.

P04---- the time that the frequency converter pump is switched to the power frequency pump. When P03=6,7,12,13,15, the controller's control mode is two pump, three pump and four pump cycle soft start control mode. In this mode, when the pump work to 50Hz, if the system pressure is less than the set value, will pump switching frequency pump, the length of time of the switching process, set by the P04 to control the time. Depending on the size of the pump power, this time is usually set between 0.1-5 seconds.

P05---- undervoltage and pump time. This parameter is valid when P03=3,5,6,7,8,9,11,12,13,15 is valid. When a pump works, if the pressure does not reach the set point, when the next pump is started, the interval is P05.

P06Over time, Yajian pump. This parameter is valid when P03=3,5,6,7,8,9,11,12,13,15 is valid. When a plurality of pumps, pump system Yajian the time interval between the P06.

P07Output voltage selection. A voltage signal that controls the frequency of the inverter. There are two output options, 0--5V and 0--10V, to meet the frequency input requirements of different brands of converters.

P08- enter sensor type selection. The controller accepts three types of pressure sensor input signals. P08=1 can be directly connected to a passive remote pressure gauge, or an active output 0-5V voltage output type pressure transmitter. The 0-10V output type pressure transmitter shall be specified when ordering.

If you want to answer4-20mA (1 - 5V)The current type pressure transmitter P08=2, two input terminals in the pressure signal is needed at this time (IN and GND) precision resistance between an external 250 ohm 0.5W, or when ordering directly from manufacturers in the controller plus.

If you want to answer0-20mAThe current type pressure transmitter P08=1, two input terminals in the pressure signal is needed at this time (IN and GND) precision resistance between an external 250 ohm 0.5W, or when ordering directly from manufacturers in the controller plus.

P09----

P10----

P11----P11

P12----P03=1,2,6,7,12,13,14,15P12=1,

P13----

P14----

P15----P18=1P15

P16----0~10V

P17----P17=0

P18----0~10VP18=0,0~10VP18=1,0~10VP15P18=1PVP15""""0~10V

P19----

P20----P03=1,2,3,4,5,6,10>=P20G3P20=0

P21----P03=5P21

P22----P22=0P22>0,0~10VP27<=P22<=P01-P31

P23----P23=0P03=1,2,6,7,15P23=1<=P24P28B450HzP05P03=1,2,6,7,15P23=2<=P24P28G4,P01P21()P05P01B4G4

P24----P24P28,

P25----<=P25,>=P26,,PV1Er1

P26----P25P26=0P265

P27----P22>0,P27<=P22,

P28----P23>0<=P24,P28

P29----

P30----0~10V

P31----<=((P01P02)-P31)

P32----P32=0,P32=1,P01P02P32=2,L1—L6P46—P51

L1----- H1-----

L2----- H2-----

L3----- H3-----

P39----

L4----- H4-----

L5----- H5-----

L6----- H6-----

P46-----

P47-----

P48-----

P49-----

P50-----

P51-----

P52-----Upper set pressure setting. When the pressure >=P52 is measured, all the running signals and contacts are fully closed and disconnected after 2 seconds.

Six function description of external input terminal

DI1 second pressure / fire signal input. When the DI1 and CM2 terminals are closed for more than two seconds, the pressure setting value is changed to second, the pressure setting value P02, which can also be changed and stored on the panel at this time. After the disconnection, the setting value is restored to the first pressure setting value and can be directly changed and stored on the panel.

DI2 stop signal (or water shortage test).When the DI2 and CM2 terminals are closed for more than two seconds, all outputs of the controller are turned off, including the 0~10V output. Both settings and measurements are normal. The output is closed in the order of 0~10V 3 seconds off first, turn off RUN (CM1, FWD) 2 seconds, turn off the variable frequency pump relay, and finally turn off the power frequency relay (first stop), the interval of 2 seconds. When(P02-P01) >=0.2MPaWhen the DI2 stop signal is closed or not, the controller does not stop, and when the fire condition is guaranteed, the controller does not stop. When power is on, check the DI2 status first. If it is in a closed state, the output will not move and the other will be normal. When the DI2 is disconnected for two seconds, the controller starts the action.

Seven, system current time adjustment

Hold down"S"Key, when the display window displays prompt information, loosens"S"Key, enter parameter settings, press""Button to turn the parameters of P39, the display six digit display window is the current system time, according to the" ^ "modify the hour, according to the" print "button to modify the minutes and seconds cannot be modified. When the time changes are complete, click"S"The key exits the time setting state.

When the system is in a timed shutdown state, the display window displays the current system time, while the five lights blink alternately to indicate a timed shutdown. Periodically shutdown, you can enter the parameter setting state, by modifying the P32=0, you can cancel the timing status.

In case ofManual temporary bootPress the "M" button for 3 seconds to release the message when prompted, and the system is temporarily switched on. At this point, press the "M" button for 3 seconds to release the message when prompted, and the system is in a timed shutdown.Note: only when P32=1 and 2, the "M" key has this function

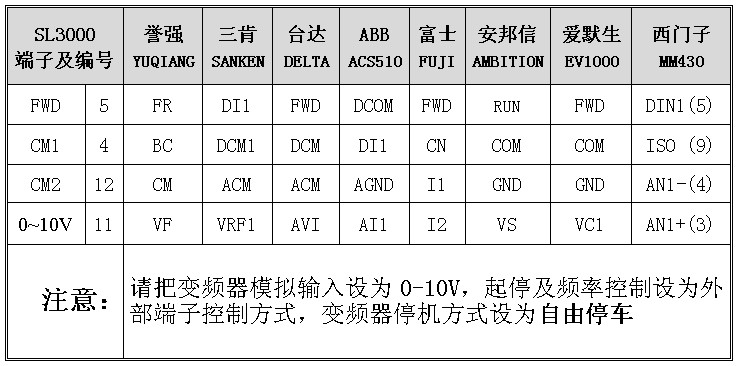

Eight controller terminal and part of frequency converter terminal connection table

Nine,SL3000Schematic diagram of connection between controller and pressure transmitter

Note: connect the 4-20mA current sensor, P08=2

Ten:Matters needing attention

1When the pump is circulating, the control contactor of soft start shall be interlocked when wiring.

2When the contactor current controller driver more than 12A, between the controller and the contactor with intermediate relay contactor or small drive, or when the power contactor action, may produce strong electromagnetic interference to the controller misoperate unforeseen.

3The functions of time switch machine, time share, partial pressure, water supply function and communication function are optional functions of the controller. The ordinary controller does not have these two functions, and needs to be specified when ordering.

4Because the products are in use to constantly upgrade and improve, such as the use of manual or individual parameters and the actual product description does not match, without notice, are based on actual products or advice to the dealers and manufacturers.

We are proud to offer international shipping services that currently operate in over 200 countries and islands world wide. Nothing means more to us than bringing our customers great value and service. We will continue to grow to meet the needs of all our customers, delivering a service beyond all expectation anywhere in the world.

Packages from our warehouse in China will be shipped by ePacket or EMS depending on the weight and size of the product. Packages shipped from our US warehouse are shipped through USPS.

Yes. We provide free shipping to over 200 countries around the world. However, there are some location we are unable to ship to. If you happen to be located in one of those countries we will contact you.

We are not responsible for any custom fees once the items have shipped. By purchasing our products, you consent that one or more packages may be shipped to you and may get custom fees when they arrive to your country.

Shipping time varies by location. These are our estimates:

| Location | *Estimated Shipping Time |

|---|---|

| United States | 10-30 Business days |

| Canada, Europe | 10-30 Business days |

| Australia, New Zealand | 10-30 Business days |

| Central & South America | 15-30 Business days |

Yes, you will receive an email once your order ships that contains your tracking information.

For some shipping companies, it takes 2-5 business days for the tracking information to update on the system.

For logistical reasons, items in the same purchase will sometimes be sent in separate packages, even if you've specified combined shipping.

If you have any other questions, please contact us and we will do our best to help you out.

All orders can be cancelled until they are shipped. If your order has been paid and you need to make a change or cancel an order, you must contact us within 12 hours. Once the packaging and shipping process has started, it can no longer be cancelled.

Your satisfaction is our #1 priority. Therefore, if you’d like a refund you can request one no matter the reason.

If you did not receive the product within the guaranteed time(45 days not including 2-5 day processing) you can request a refund or a reshipment.

If you received the wrong item you can request a refund or a reshipment.

If you do not want the product you’ve receive you may request a refund but you must return the item at your expense and the item must be unused.

*You can submit refund requests within 15 days after the guaranteed period for delivery (45 days) has expired. You can do it by sending a message on Contact Us page

If you are approved for a refund, then your refund will be processed, and a credit will automatically be applied to your credit card or original method of payment, within 14 days.

If for any reason you would like to exchange your product, perhaps for a different size in clothing. You must contact us first and we will guide you through the steps.

Please do not send your purchase back to us unless we authorise you to do so.

Thank you for your interest doing business with us!

If you would like to get a discounted price for your large purchase orders, fill in the required blanks along with your email address, the product Item ID # and/or the link of the item that you want to order, item quantity (minimum of 30 pieces), shipping country and payment method is required. We will contact you with a discounted price as soon as we receive your inquiry.© 2017-2023 HOGAKI.COM - Home, Garden & Kitchen shop.